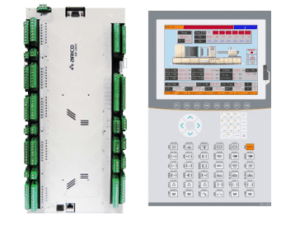

Devanshi Electronics presents the Plastic Machine Controller (PMC)—a rugged, high-performance control solution purpose-built for injection molding, blow molding, extrusion, and packaging machinery. With expertise in retrofitting existing systems or equipping new production lines, Devanshi delivers precision, uptime, and seamless integration to manufacturers across the plastic processing industry

• Fast software interrupt timing is 0.25ms apply to control, enhance the accuracy of more

than 2 times the displacement

• Fast software interrupt timing is 0.25ms apply to control, enhance the accuracy of more

than 2 times the displacement

•

It is simple to update all of program via USB memory driver

•

DCS control (HMI and Remote I/O module) for easy access of external device and/or controller

•

Various HMI size options: 5.6″, 8″, 10.4″ and 12.1″ or touch panel(10.4″ & 12.1″)

•

3 of high speed 32 bits CPU (260MHz)

•

High speed Ethernet communication between HMI and Remote I/O module

•

RS485 and SKY-Link(Option) Interface

•

State-of-the-art window system HMI Screen Editor design by ARICO

•

PLC ladder editor for process program

•

The Demolished architecture, CPU board can be upgraded to more powerful new one on base main control board

•

It is non-industrial personal computer board, because the CPU of PC update very fast, face stop manufacture and version change, software maintain and cost will go high

| AR2100 | Technical Specification |

|---|---|

| PLC CPU | 520MHz |

| Control CPU | 520MHz Time base = 0.25ms 1. Higher control precision 2. Software can be updated through USB |

| IO Connection | PNP |

| Temperature PID Control | 8 |

| D/I Digital Input | 32 / 48 |

| D/O Digital Output | 32 / 48 |

| A/D Analog Input | 16 bit * 8 |

| Start/Stop Input | X |

| FDA Analog Output | X |

| D/A Analog Output | 12 bit * 8/12(0~±10v) |

| PWM Output | X |

| RPM Count | 3 |

| FPGA | PLC CPU & Control CPU data transmitted through a parallel FPGA connection; allows more precise control accuracy |

| AR2100 | Technical Specification |

|---|---|

| Temperature Module | Man-machine communication allows 15 sets of temperature module expansions; each module includes 8-stage temperature control |

| IO Expansion Module | Able to expand 12 modules; each module DI / DO * 16 (Max=192) |

| A/D Expansion Module | 16 bit*8 |

| Encoder Expansion Module | 32 bit*4 |

| Controller | AR1260 | AR2000 | AR2010 | AR2100 |

|---|---|---|---|---|

| PLC CPU | 266MHz | 520MHz | — | — |

| Control CPU | 266MHz Time base = 0.25ms |

520MHz Time base = 0.25ms |

1. Higher control precision 2. Software can be updated through USB |

|

| IO Connection | NPN | NPN | NPN | PNP |

| Temperature PID Control | 8 | |||

| D/I Digital Input | 32 | 32 / 48 | ||

| D/O Digital Output | 32 | 32 / 48 | ||

| A/D Analog Input | 14 bit * 6 | 16 bit * 6 | 16 bit * 8 | |

| Start/Stop Input | X | 0 / 4 | X | |

| FDA Analog Output | 12 bit * 5 (0~+10v) | 12 bit * 4 (0~+10v) | X | |

| D/A Analog Output | ||||

| PWM Output | X | 1 | X | |

| RPM Count | 1 | 3 | ||

| FPGA | PLC CPU & Control CPU data transmitted through a parallel FPGA connection; allows more precise control accuracy | |||

| Controller | AR1260 | AR2000 | AR2010 | AR2100 |

|---|---|---|---|---|

| Temperature Module | Man-machine communication allows 15 sets of temperature module expansions; each module includes 8-stage temperature control | |||

| IO Expansion Module | DI / DO * 8 (Max) | Able to expand 12 modules; each module DI / DO * 16 (Max=192) | ||

| A/D Expansion Module | X | X | 16 bit * 8 | |

| Encoder Expansion Module | X | 32 bit * 4 | ||

©Copyright 2025 Devanshi Electronics Pvt Ltd All Rights Reserved. (terms Of Use) Developed And Managed By SME Business Services Ltd